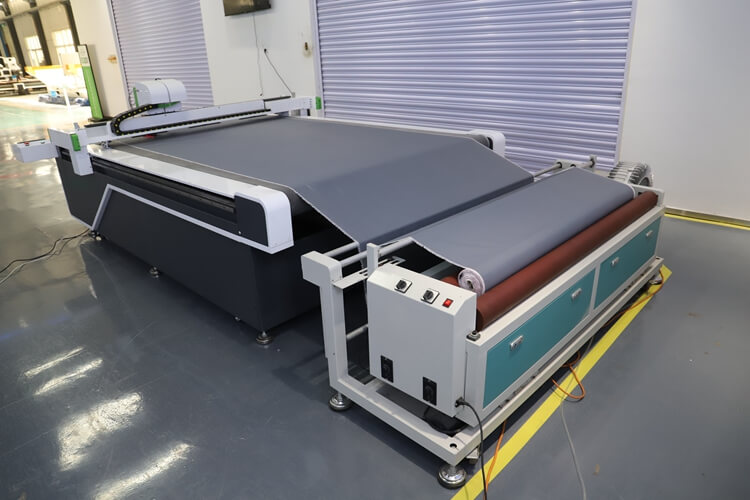

Automatic Cloth Cutting Machine

Automatic Cloth Cutting Machine

An Industrial Automatic Cloth Cutting Machine is a highly efficient and precise tool used in various industries. oscillating cutting machine is a specialized tool designed to cut various materials using a blade that moves in a rapid back-and-forth (oscillating) motion. These machines are widely used in industries such as textiles, automotive, packaging, and construction due to their precision and versatility.

Industrial Cloth Cutting Machine

Industrial Cloth cutting machines equipped with vibrating knives utilize rapid oscillating movements to cut through fabric with precision and speed. The vibrating knife moves back and forth at high frequencies, allowing it to slice through multiple fabric layers simultaneously. This oscillating action, combined with adjustable cutting pressure, enables smooth and accurate cuts without damaging the textiles.

The cutting plotter cuts with vibriting knife, not by laser. So it causes no burning to the materials. No smell.

CNC Cloth knife cutting machines are suitable for small businesses that want to increase production efficiency, reduce labor costs, and improve product quality. However, small businesses should consider their budget and production volume when investing in CNC knife cutting machines. It’s important to choose a machine that suits the business’s specific needs and has a reasonable return on investment. Finally, adequate operator training is essential to fully utilize the technology and maximize the benefits.

Advantages of Automatic Cloth Cutting Machine

- Increased Productivity

- Vibrating knife technology allows fabric cutting machines to achieve incredibly high cutting speeds without compromising quality. This significantly improves productivity and enables bulk production of garments, home textiles, and other fabric-based products.

- Precise Multi-Layer Cutting

- The oscillating motion of a vibrating knife facilitates precise cutting through multiple fabric layers in one pass. This stacked cutting capability is ideal for industrial applications requiring high-volume production of pattern pieces.

- Minimal Cloth Damage

- Unlike rotating blades, vibrating knives apply an even pressure along the entire cutting edge, reducing friction and heat buildup. This results in clean cuts with less fabric distortion, frayed edges or burn marks.

- Longer Blade Life

- Vibrating knives experience less wear and tear compared to rotating blades since there is no grinding action during cutting. As a result, vibrating knife blades can last up to 10 times longer, reducing overall replacement costs.

- Customizable Settings

- The oscillation frequency and cutting pressure of vibrating knives can be customized based on the Cloth thickness and density. This ensures optimal performance for a wide variety of materials.

Benefits of Using a CNC Cloth Cutting Machine:

Accuracy: Minimizes material wastage and ensures high precision in cutting.

Efficiency: Enhances production speed and reduces downtime.

Cost-Effective: Lowers labor costs and reduces fabric wastage.

Consistency: Produces uniform cuts and maintains consistent quality.

Flexibility: Adaptable to various production needs and can handle different textilest ypes.

Automatic Cloth Cutting Machine Applications:

Fashion Industry: Used for cutting patterns for garments and accessories.

Automotive Industry: Cuts materials for car interiors, seat covers, and upholstery.

Furniture Manufacturing: Used for cutting fabric for sofas, chairs, and other upholstered furniture.

Textile Industry: General fabric cutting for various textile products.

Choosing an Industrial Fabric Cutting Machine

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments