CNC Wood Cutting And Drilling Machining Center

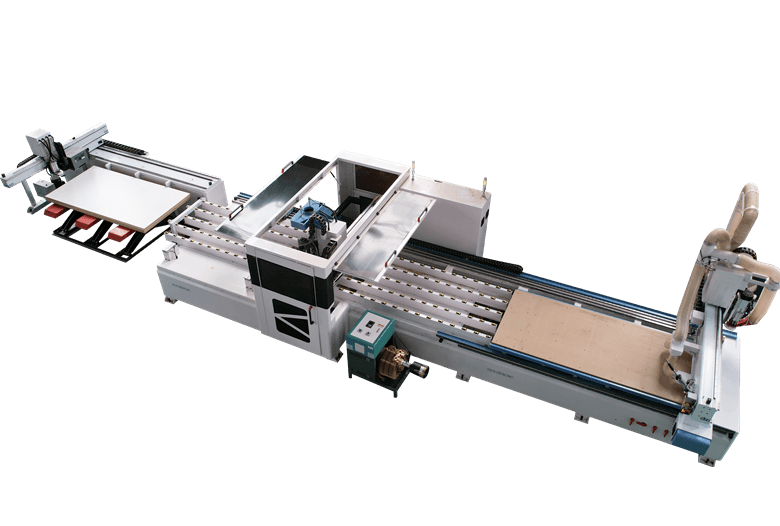

High-speed CNC drilling and cutting machining center is a set of drilling, grooving, cutting as one of the processing equipment, the machine is composed of automatic labeling machine, drilling area, cutting area three parts, only need to place the plate on the labeling platform, the machine can be automatic labeling, front and back drilling and grooving, cutting and other processing steps, can also be matched with edge sealing machine, The production process of panel furniture can be completed;

Smart Wood CNC Cutting Drilling Machine

High-speed CNC drilling and cutting machining center is a set of drilling, grooving, cutting as one of the processing equipment, the machine is composed of automatic labeling machine, drilling area, cutting area three parts, only need to place the plate on the labeling platform, the machine can be automatic labeling, front and back drilling and grooving, cutting and other processing steps, can also be matched with edge sealing machine, The production process of panel furniture can be completed;

Equipment operation is simple, high efficiency, high precision, so that the production is more time saving, saving materials, saving labor, is the only choice for plate furniture enterprises.

Full automatic CNC router is mainly designed for customized furniture plans, such as kitchen cabinet and wardrobe, the whole production line only need one ordinary worker to operate.

1. Automatic Feeding

Suck the board to the next process automatically.

2. Automatic Labeling

The machine can show a barcode / order No. / board size information on each board. The label information can be customized according to your requirements.

3. Automatic CNC Machining

Cutting, milling, drilling and engraving automatically.

4. Automatic Discharge

After process, the boards are discharged automatically.

Full Automatic Flatbed CNC Router Advanced Performance

① Automatic labeling: completely replace the dependence on manual labeling, paste the label well before processing, truly realize intelligence, save labor, save time, and effectively avoid manual labeling errors;

(2) Bed integrated design: double side drilling unit and cutting unit integrated design, the whole plate and then the double side drilling unit drilling, directly and automatically transported to the cutting unit, higher accuracy; More efficient;

③ Reduce the production process: the plate drilling is completed in the opening drilling machine and the edge banding machine, the drilling link does not need manual intervention, eliminating the traditional edge banding and then manually get the drilling link on the six sides of the drill;

④ Improve production efficiency: the upper and lower drilling of the whole plate is faster and more efficient than the piece-by-piece processing of the smaller allegro;

⑤ Reduce the damage of the plate in the production process: while building the production process, it reduces the transmission and handling of the plate in the production process, effectively reducing the damage of the plate;

High degree of automation: compared with the traditional stand-alone equipment, the manual only needs to pick up the board and turn to the edge banding machine, which greatly improves the degree of automation in the production process;

Low failure rate, easy to operate: compared with traditional automated production lines, easier to operate, lower failure rate;

CNC Woodworking Cutting and Drilling Machining Center

Woodworking Cutting and Drilling CNC Machining Center

CNC nesting machining centres for cutting and drilling are high-performance and reliable machines, specifically designed for manufacturers who need to produce in batches or in single orders. Precision in machining even the most difficult workpieces, high speeds and maximum flexibility are guaranteed by this all-in-one technology, increasingly functional and intelligent.

The machining center is equipped with saw blade spindle, linear tool changer, and automatic loading and unloading platform. With automatic labeling system, it can help improve efficiency and reduce labor costs.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments