CNC Machine for Marble and Granite

Granite CNC Machine

A granite CNC machine, also known as a CNC router or CNC stone cutting machine, is a computer-controlled cutting machine specifically designed for granite and other stone materials. These machines utilize rotating cutting tools, such as diamond-tipped router bits or saw blades, to cut, shape, and polish granite according to precise digital designs. The movements of the machine are guided by a computer program, which translates the design into precise cutting instructions.

CNC Granite Bridge Saw

Whether it is 5 axis CNC bridge saw, 4 axis bridge cutting machine, or 3 axis stone cutting bridge saw, they are all multi-functional, easy to operate, labor saving, fast, precise, economical, and practical. Moreover, we support machine customization to realize your bridge saw cutting designs and projects.

Bridge saw machine is a type of stone cutting machine designed for diversified stone business. And CNC stone bridge cutters are cutting machines made for cutting natural stone, granite, marble, and ceramics. With a CNC stone saw, it is good at special-shaped cutting, polishing, edging, drilling, and chamfering of granite, marble, quartz, artificial stone, and natural stone. Therefore, it is also known as stone bridge saw cutting machine, stone bridge saw for quartz, bridge saw for granite, tile bridge saw, marble bridge cutting machine, stone bridge saw cutter, etc.

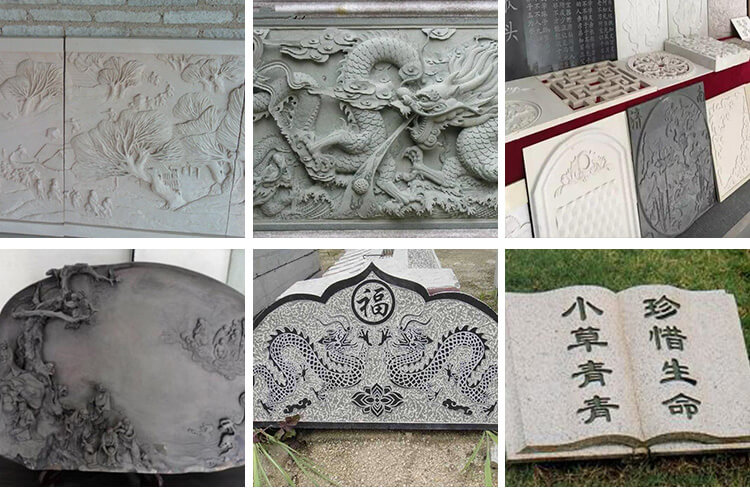

CNC Granite Engraving Machine

cnc granite engraving machine utilize various cutting tools and bits to perform different operations on stone materials. The choice of tool depends on the desired outcome and the properties of the stone being machined. Common cutting tools for stone CNC routers include diamond-tipped router bits, end mills, core drills, and engraving tools.

A stone cnc engraving machine with a rotary axis is a specialized type of CNC machine designed for cutting, carving, and engraving stone materials. The rotary axis, also known as a fourth axis or indexer, enables the machine to rotate the stone workpiece in order to create three-dimensional or cylindrical shapes and perform intricate designs on the stone.

This is a stone cnc router machine with rotary axis, this machine can be used to produce stone column and tombstone.As a CNC stone column machine, it has installed the rotary axis, which can add greater functionality to the machine’s capabilities allowing for 4-axis cutting in both 2D and 3D carving and indexing functions.Moreover this marble, granite engraving machine also has a higher Z axis, which can improve the cut precision.if you like this stone engraving machine for sale, please contact us, we will give you an affordable price.

Granite Countertop CNC Machine

CNC stone machining center -quartz stone cabinet countertops processing, stone side modeling, arc retaining water grinding, basin pots, stone relief, hollow, line carving. Granite, marble, bluestone, tombstone, headstone and other stone materials processing. One-key intelligent completion of conventional blanking, 45° bevel cutting, multi-angle arbitrary cutting, curve cutting, internal angle and basin hole cutting and other processes.Now, the affordable CNC stone machining machine is sold at the best price.

5 Axis Waterjet Cutting Machine

A waterjet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance, such as metal, stone or glass,machine equipment shell, metal parts.

Waterjet cutting is often used during the fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods; examples of such materials include plastic and aluminium. Waterjet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.

CNC Granite Cutting Machine for Sale

The capabilities of a granite CNC machine are vast and diverse. Here are some of the key features and functions that make these machines so powerful:

- Cutting and Shaping: A granite CNC machine can cut and shape granite with incredible precision. Whether it’s cutting slabs into specific dimensions, creating intricate patterns, or shaping curved edges, these machines can handle a wide range of stone fabrication tasks.

- Edge Profiling: Granite countertops often require precise edge profiles, such as bullnose, bevel, or ogee. A granite CNC machine can create these profiles with ease, ensuring a professional and polished finish.

- Engraving and Inlay Work: With the ability to control the depth of cut, a granite CNC machine is perfect for engraving and inlay work on granite surfaces. Intricate designs, logos, or text can be etched into the granite, adding a personalized and artistic touch.

- Polishing: Granite CNC machines are equipped with polishing tools that can bring out the natural shine and luster of the stone. From honing to high-gloss polishing, these machines can achieve a flawless and mirror-like finish on granite surfaces.

- Complex Shapes: With the right software and tooling, a granite CNC machine can create complex shapes and contours on granite. This opens up possibilities for creating unique and custom-designed stone elements for architectural and artistic purposes.

Applications of Granite CNC Machine

The applications of granite CNC machines are vast and varied. Here are some of the industries and projects where these machines excel:

- Countertop Fabrication: Granite CNC machines are widely used in the fabrication of granite countertops. They can cut, shape, and polish granite slabs to precise dimensions, creating beautiful and durable countertops for kitchens, bathrooms, and other surfaces.

- Flooring and Wall Cladding: Granite CNC machines can also be used to fabricate granite flooring tiles and wall cladding panels. These machines can cut and shape large granite slabs into uniform tiles or panels, ensuring a seamless and visually appealing installation.

- Monument and Memorial Engraving: Granite CNC machines are commonly used in the creation of monuments and memorials. They can engrave intricate designs, names, and dates onto granite surfaces, preserving memories and honoring loved ones.

- Architectural Elements: From columns and balustrades to fireplace surrounds and decorative accents, granite CNC machines can create custom-designed architectural elements. These machines can shape and carve granite into intricate and ornate details that add elegance and grandeur to any architectural project.

- Artistic Sculptures: Granite CNC machines have also found their way into the world of art. Artists and sculptors use these machines to transform blocks of granite into stunning sculptures and installations. The precision and versatility of the machines allow for intricate and detailed artistic expressions.

The Benefits of Using a Granite CNC Machine

The adoption of granite CNC machines has brought numerous benefits to stone fabricators and manufacturers. Here are some of the key advantages:

- Precision and Accuracy: A granite CNC machine eliminates the potential for human error, ensuring precise and accurate cuts every time. This level of precision is crucial for achieving seamless joints, consistent dimensions, and a high-quality finish.

- Time Efficiency: With the ability to automate tasks and perform multiple operations simultaneously, a granite CNC machine significantly reduces production time. This allows stone fabricators to handle more projects and meet tight deadlines without compromising quality.

- Material Optimization: By optimizing the placement of cuts and minimizing waste, a granite CNC machine helps maximize material utilization. This not only reduces costs but also contributes to a more sustainable approach to stone fabrication.

- Versatility: From cutting and shaping to polishing and engraving, a granite CNC machine offers unparalleled versatility. It can handle a wide range of stone fabrication tasks, making it an indispensable tool for both small-scale artisans and large-scale manufacturers.

- Safety: Granite CNC machines are designed with safety features to protect operators and minimize the risk of accidents. These features include emergency stop buttons, safety interlocks, and protective enclosures, ensuring a safe working environment.

Granite CNC Machine FAQ

1. How does a granite CNC machine work?

A granite CNC machine works by utilizing computer-controlled movements to guide cutting tools in the process of cutting, shaping, and polishing granite. The machine follows precise instructions from a digital design to achieve accurate and intricate results.

2. Can a granite CNC machine work with other stone materials?

While granite CNC machines are primarily designed for granite, they can also work with other stone materials such as marble, quartz, and limestone. The cutting tools and settings can be adjusted to accommodate different stone types.

3. What software is used to operate a granite CNC machine?

Various software options are available for operating granite CNC machine. Some popular choices include AutoCAD, SolidWorks, and ArtCAM. These software programs allow users to create and modify digital designs, which are then translated into machine instructions.

4. Is training required to operate a granite CNC machine?

Yes, training is essential to operate a granite CNC machine effectively and safely. Operators need to understand the machine’s controls, software interface, and safety protocols. Training programs are available to provide the necessary knowledge and skills.

5. Can a granite CNC machine be used for small-scale projects?

Absolutely! Granite CNC machines are versatile and can be used for both small-scale and large-scale projects. Whether you’re a small artisan or a large manufacturer, a granite CNC machine can cater to your specific needs and requirements.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments